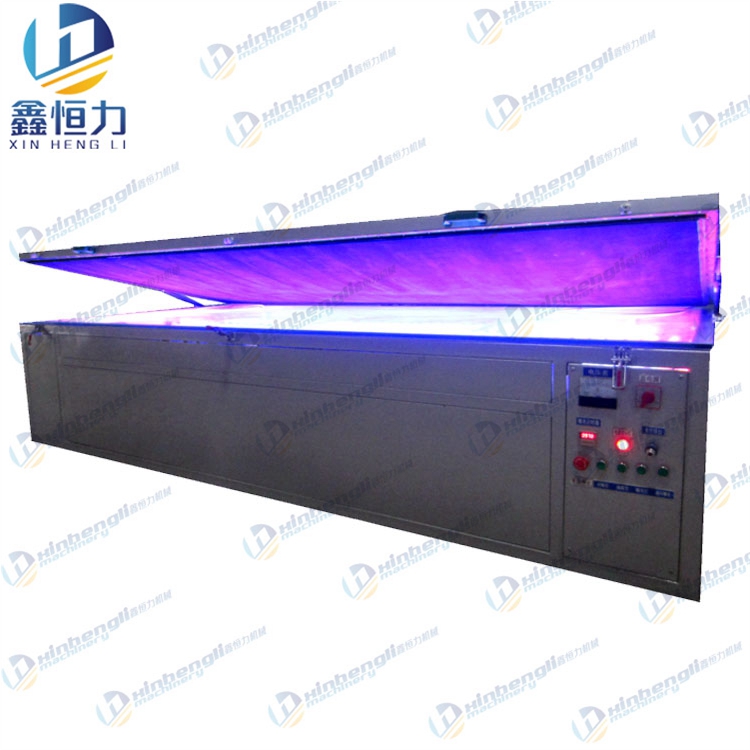

Equipment use:

The exposure machine is a metal corrosion processing pre-processing equipment, which is mainly used for surface exposure of a 48-foot stainless steel decorative board to perform pattern transfer.

Machine parameters:

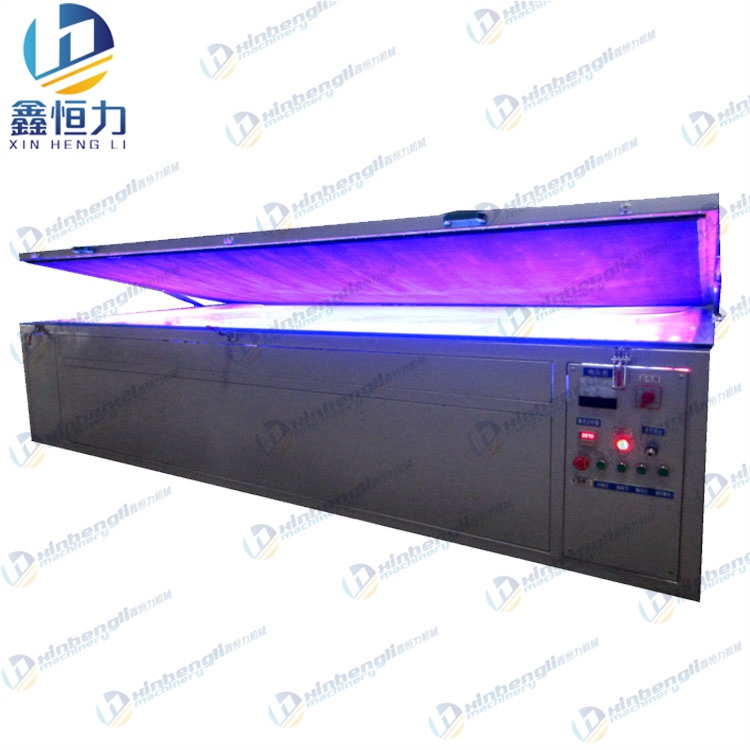

Equipment outer diameter: 5000*1400*1200mm;

Effective exposure area: 1300*4500mm;

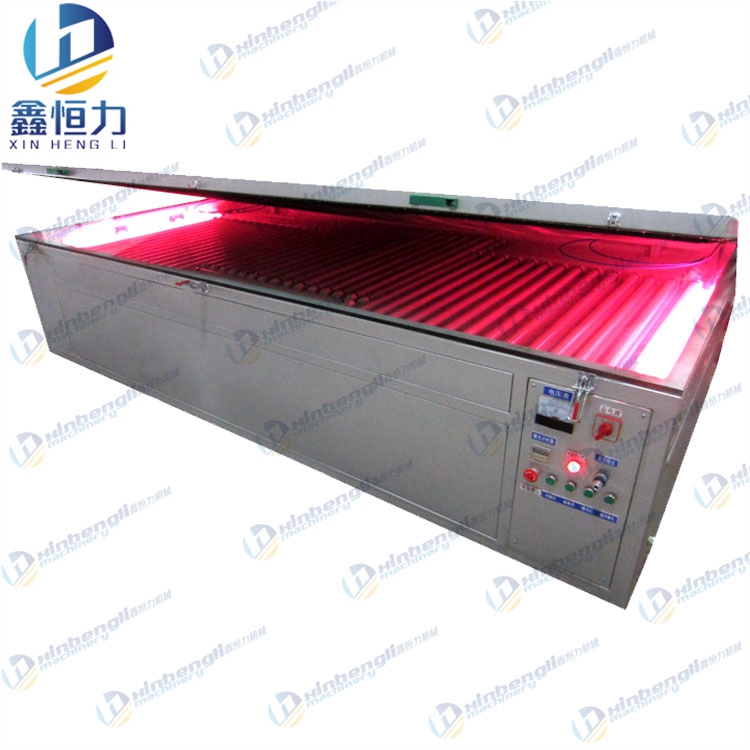

Light source system: 2KW UV lamp *4;

Vacuum pump: 1 set, strong suction

Upper layer: blanket, lower layer: tempered glass

Power: 8KW

Power supply: 380V/50HZ

working principle:

The vacuum pump is used to extract the indoor air, so that the vacuum pressure is generated in the chamber to force the printing plate and the manuscript to adhere to the glass plane, and then the light source exposes the photosensitive layer of the printing plate within a predetermined exposure time, the exposure is finished, and the air is automatically deflated to complete the whole process.

Equipment advantages:

1. The exposure machine is easy to operate, and the exposure light source adopts a fast-starting high-power ultraviolet lamp, the light intensity is stable and uniform, and the ultraviolet spectrum is evenly distributed;

2. The machine is composed of lamps and controllers. The light source is two special metal halide lamps with a wavelength range of 360-400mm and high luminous efficiency.

3. The imported aluminum reflector has the characteristics of high reflective efficiency, which not only saves energy, but also improves the use efficiency of the lamp;

4. The exposure time can be adjusted freely, the operation is simple and easy to understand, and it is suitable for high-quality exposure such as metal etching and printed circuit board.