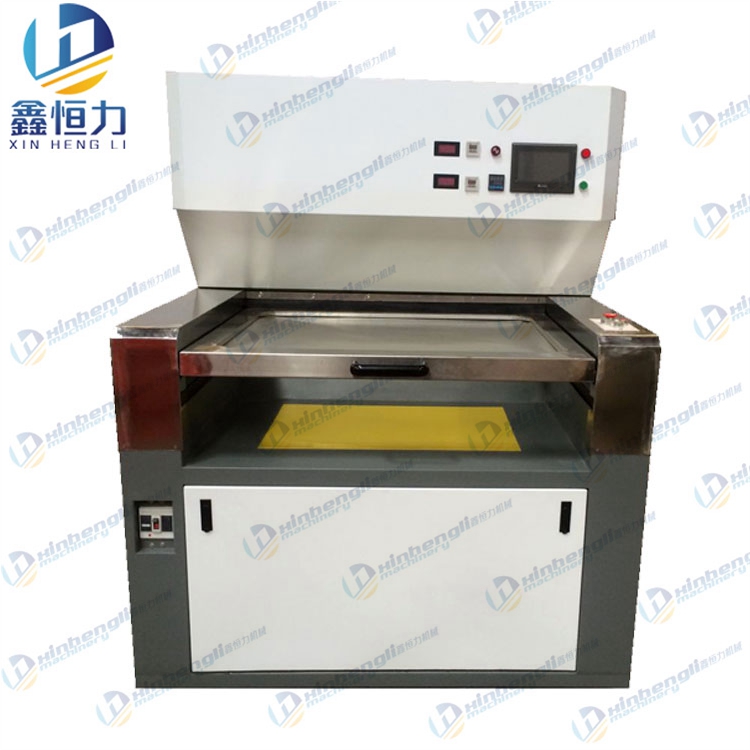

Equipment use:

The fully automatic parallel light exposure machine is a pre-corrosion processing equipment, which is suitable for products with high precision, such as: filter, screen, watch dial and other product exposure, which can realize continuous mass production.

Machine parameters:

Equipment outer diameter: 2700*1400*1800mm;

Effective exposure area: 660*880mm;

Light source system: UV5KW*2;

Light wavelength: 300-425 nm;

Exposure control: UV energy totalizer;

Illumination uniformity: 95% or more;

Vacuum device: dry vacuum pumping, vacuum pressure above 650mm/kg under normal operation;

Exposure frame: upper layer: MAYLAR film lower layer: tempered glass;

Cooling water source: 10-15 ° C 25 L / min;

Control method: touch human machine interface;

Monitoring system: self-diagnosis function and abnormal message prompts;

Countertop cooling method: forced air cooling;

Lamp cooling method: cooling of the refrigerator;

Power: 13KW;

Power supply: 380V/50HZ

working principle:

The vacuum pump is used to extract the indoor air, so that the chamber forms a vacuum pressure to force the film and the workpiece to adhere to the glass plane, and then the light source exposes the photosensitive layer within a predetermined exposure time, the exposure ends, and the air is automatically deflated to complete the entire process.

Equipment advantages:

1. This machine adopts automatic/manual control and Chinese display;

2. Ultra-high speed double-face entry and exit system to fully improve exposure efficiency;

3. The exposure amount can be freely set through the human machine interface, and the system can memorize the exposure conditions;

4. It adopts German original high-reflection fine angle lampshade and high-efficiency exposure system to bring stable light source working environment and extend lamp life;

5. Humanized comprehensive abnormal alarm system to ensure the safety of machine use;

6. The exposure time can be adjusted freely. The operation is simple and easy to understand. It is suitable for high-quality exposure such as metal etching and printed circuit board. It can improve your production efficiency and is a good helper for reducing production cost.