Phone: +86 18927756652 (Wechat)

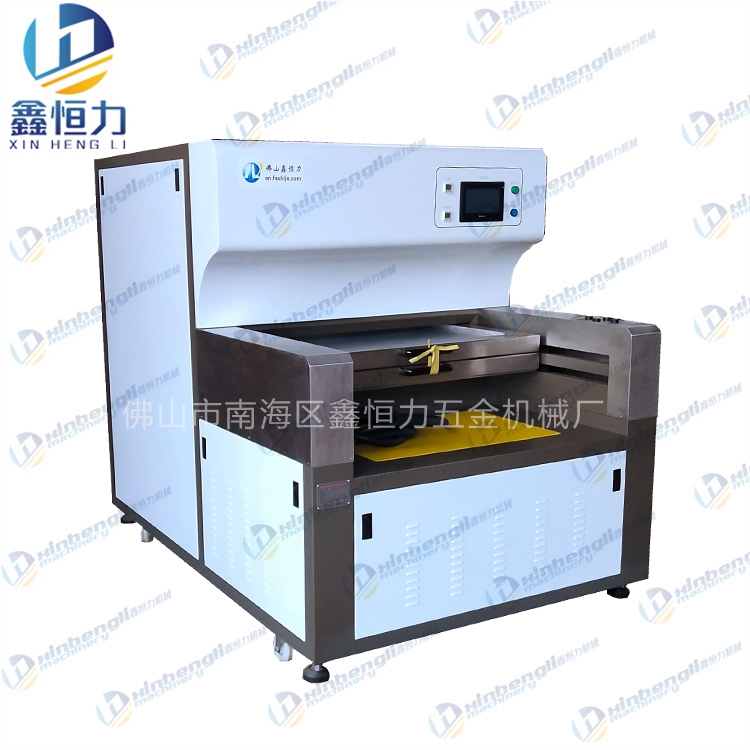

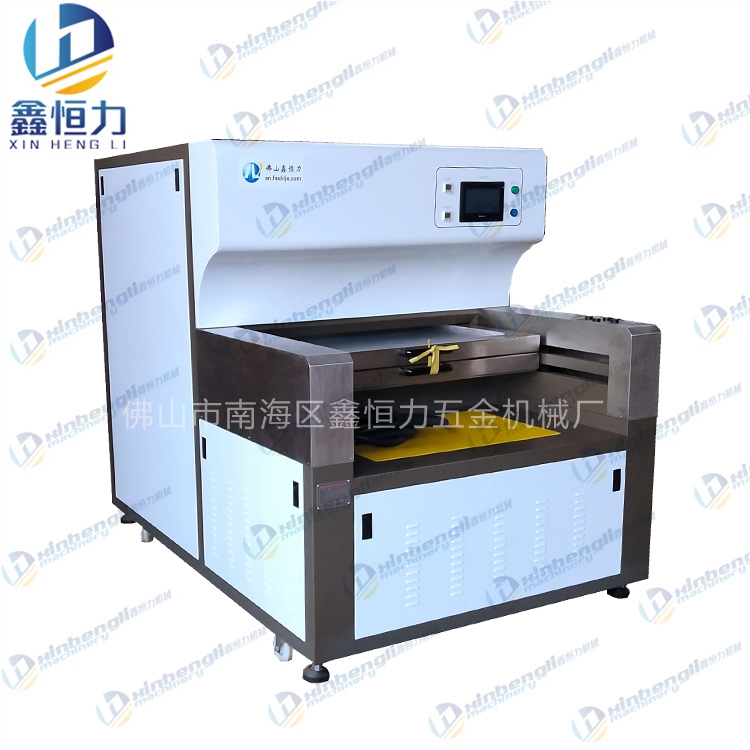

Etch machine_Etch machine Manufactor_Guangdong Xin Hengli equipment manufacturer

Landline: 0757-86677701

Web: www.fsxhljx.com

E-mail: 7587727@qq.com

Address: Guicheng, Nanhai District, Foshan, Guangdong Province, China

The LED precision double-sided exposure machine is a metal corrosion processing pre-processing equipment, mainly used for double-sided hollowing out of stainless steel filters, screens, watch discs, gears and other precision products for graphic transfer.

The LED precision double-sided exposure machine is a metal corrosion processing pre-processing equipment, which is mainly used for double-sided hollowing out of precision products such as stainless steel filters, screens, watch discs, gears and so on for graphic transfer.

Machine parameters:

Equipment outer diameter: 2000*1700*1650mm;

Effective exposure area: 660*880mm;

Light source system: LED light source;

Vacuum pump: 2 sets, strong suction

Table cooling method: forced air cooling;

Lamp cooling method: refrigerator cooling;

Power: 3KW;

Power supply: 220V/50HZ;

working principle:

Using a vacuum pump to draw out the indoor air, the vacuum pressure is formed in the room to force the plate and the manuscript to adhere to the glass plane, and then the light source exposes the photosensitive layer of the plate within a predetermined exposure time. After the exposure is completed, the entire process is automatically deflated.

Equipment advantages:

1. The exposure machine is easy to operate, the exposure light source adopts quick-start high-power ultraviolet lamp, the light intensity is stable and uniform, and the ultraviolet spectrum distribution is uniform;

2. The machine is composed of lamps and controllers, the light source is LED light source, the wavelength range is 360-400mm, the luminous efficiency is high, and more energy-saving;

3. Adopt German original high-reflectivity precision-angle lampshade and high-efficiency exposure system, which bring stable working environment of light source and prolong lamp life;

4. The exposure time can be adjusted freely. The operation is simple and easy to understand. It is suitable for high-quality exposure such as metal etching and printed circuit boards. It can comprehensively improve your production efficiency and is a good helper for you to reduce production costs.