Chemical etching

Corrosion is a technique in which a metal workpiece is removed using a chemical reaction or a physical impact.

Corrosion technology can be divided into two types: "wet etching" and "dry etching".

Generally referred to as corrosion, also known as photochemical etching, refers to the application of self-adhesive; exposure plate, development or screen printing screen image transfer, the protective ink in the area to be corroded to remove the need for corrosion, in the case of corrosion The metal contacts the chemical solution to achieve the effect of dissolving corrosion, forming the effect of unevenness or hollowing.

It can be used to manufacture printed embossed plates such as copper plate, zinc plate and stainless steel. It is also widely used in the processing of weight reduction instrument panels, billboard signs and thin workpieces that are difficult to process by traditional processing methods. The technical improvement and the development of process equipment can also be used for the processing of precision corrosion products of electronic sheet parts in the aviation, machinery and chemical industries. Especially in the semiconductor process, corrosion is an indispensable technology.

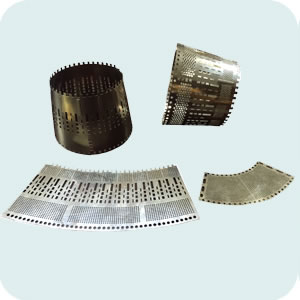

For example, stainless steel filter mesh, the round holes are formed by hollowing corrosion process.

Process: cleaning the workpiece to remove oil (stainless steel or other metal parts) --- coating --- baking dry --- exposure --- development -- etching -- peeling

Stainless steel surface chemical processing

The surface of the stainless steel product is etched with ferric chloride, and various patterns, patterns, characters, logos, and the like are drawn on the surface. The chemical etching process is to apply a protective ink or a sticker to the surface of the stainless steel that needs to be corroded now. Then, an etching solution composed of ferric chloride and a small amount of hydrochloric acid is placed, and the surface layer of the stainless steel acts on the ferric chloride, and the resulting chloride is dissolved in the etching liquid or deposited on the surface of the stainless steel.

According to the above process flow, the required equipment is:

Process 1. Coater: It is mainly used for coating the workpiece as a protective layer. The ink on the coating machine is the most advanced and mature technology of the present technology. It is characterized by uniformity, time saving, labor saving, high output, and consumables. Wait.

Process 2. Baking box: It is mainly used for baking the ink to prevent the ink from sagging and deepening the curing.

Process 2. Baking box: It is mainly used for baking the ink to prevent the ink from sagging and deepening the curing.

Process 3. Exposure machine: It is mainly used for the local photosensitive ink on the photo-solid workpiece to form image transfer. The UV-wavelength ultraviolet light is emitted by turning on the ultraviolet light to transfer the pattern on the film to the workpiece coated with the photosensitive ink.

Process 4. Developing machine: mainly used for photosensitive process, after the exposure, the surface pattern of the product is revealed, and then enters the etching process, which can realize continuous production.

Process 5. Etching machine: mainly used to corrode the exposed metal part of the workpiece, and use an etching solution to remove some metal corrosion equipment by high pressure spraying.

Process 6. Ultrasonic cleaning machine: mainly used for cleaning excess ink after corrosion to obtain a finished product.