Phone: +86 18927756652 (Wechat)

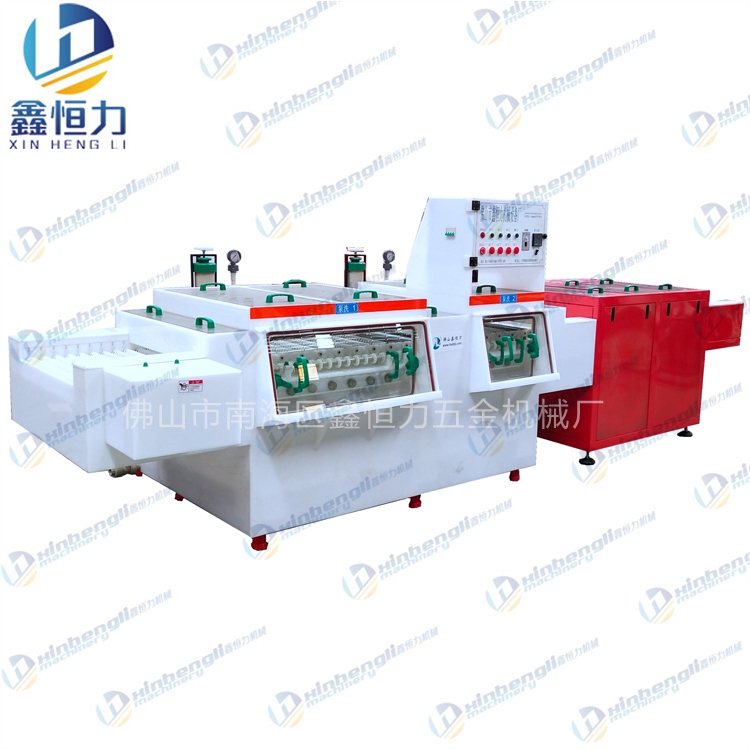

Etch machine_Etch machine Manufactor_Guangdong Xin Hengli equipment manufacturer

Landline: 0757-86677701

Web: www.fsxhljx.com

E-mail: 7587727@qq.com

Address: Guicheng, Nanhai District, Foshan, Guangdong Province, China

The development, cleaning and drying line is a supporting equipment for hardware etching pretreatment. It is mainly used for photosensitive etching process. After exposure, the surface pattern of the product is exposed, and then enters the etching process, which can achieve continuous mass production, save labor, and greatly improve work efficiency.

Uses: The development, cleaning and drying line is a supporting equipment for metal etching pretreatment. It is mainly used in the photosensitive etching process. After exposure, the surface pattern of the product is exposed, and then enters the etching process, which can achieve continuous mass production, save labor, and greatly improve Work efficiency. Process flow: feeding → developing → checking → washing → absorption → drying with cold air → drying with hot air → discharge

Machine description:

Machine model: XHL-XY71500QX;

Equipment outer diameter: 5700 * 1760 * 1500mm;

Development area: 700 * 1200mm;

Cleaning area: 700 * 1200mm

Drying section: 1300mm

Developer pump: 4.0KW * 1 unit;

Cleaning pump: 4.0KW * 1 set

Spraying method: high-pressure spraying with independent nozzles;

Filtering system: full pressure filter * 2;

Power: 15.5KW;

Power supply: 380V / 50HZ

working principle:

1. Apply a layer of photosensitive ink on the surface of the product, the ink can not see the strong light, otherwise it will solidify, resulting in the development of display;

2. After drying the ink, paste film film for exposure. Film film is a transparent black and white film. The black part will block the light and the white part will transmit light;

3. After the exposure is completed, put the product into the developing machine. At this time, the black part of the ink will be washed away and will be corroded during the etching process. On the contrary, the white part of the ink will be exposed due to the exposure, and the ink will not fall during the development process The UV ink plays protective in the corrosion process.