Equipment use:

Widely used in product baking, drying, such as etching processing industry, electroplating industry, electronics industry, alloy jewelry industry, food and plastics industry, leather industry, hardware and other production industries. Photosensitive etching process: coating → oven → exposure → development → etching → film removal → finished product

Machine parameters:

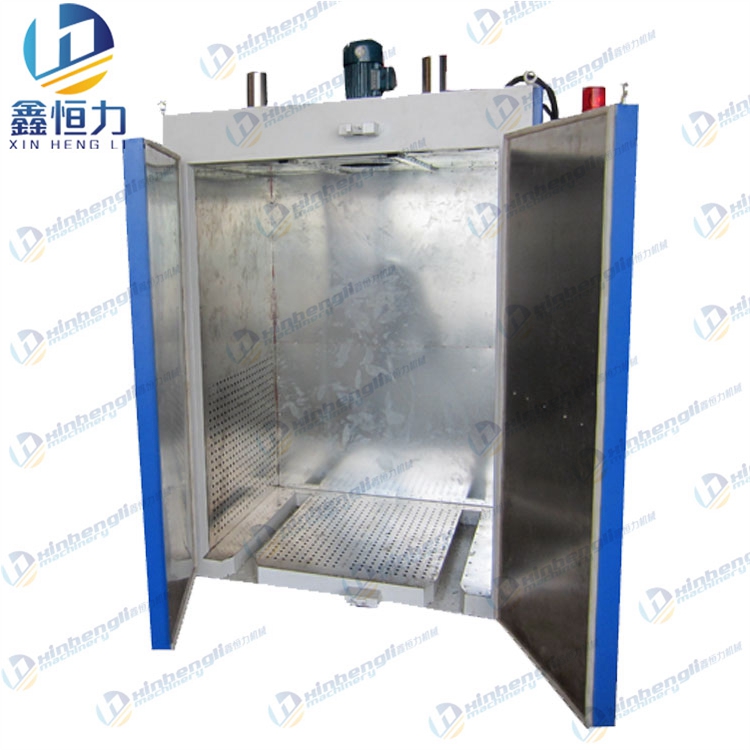

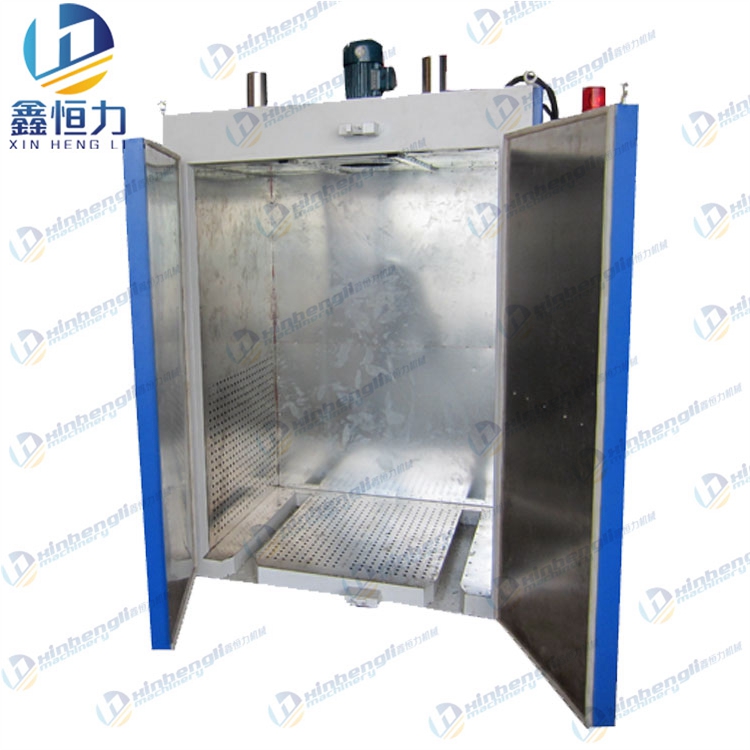

Equipment outer diameter: 1400*1000*1900mm;

Equipment inner diameter: 1200*900*1600mm;

Heating temperature: room temperature -300 ° C;

Liner material: 1.2mm stainless steel plate;

Outer box material: 1.5mm cold-rolled steel plate surface painting;

Power: 15KW

working principle:

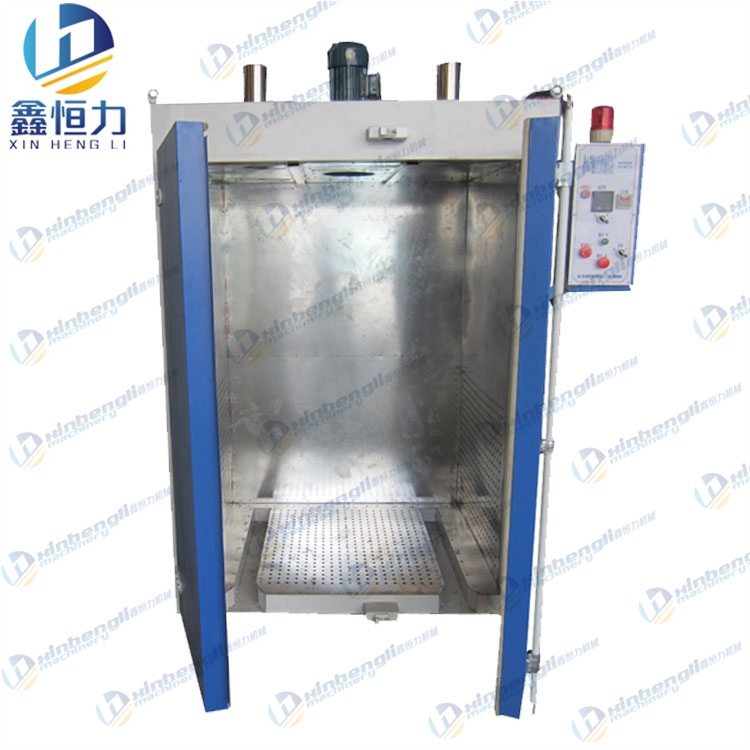

Built-in Taiwan-made stainless steel heat sink U-shaped heating tube on both sides of the furnace chamber, the top of the furnace chamber is equipped with a 0.75KW air transport motor, horizontal circulation large air volume forced air mode, equipped with intake and exhaust port valves, adjustable air flow To make the temperature inside the furnace more uniform, so as to achieve the purpose of drying.

Equipment advantages:

1. The outside of the box is made of high-quality stainless steel plate and high-temperature baking varnish on the surface. The bottom of the oven is floor-standing, which greatly facilitates the entry and exit of the cart;

2. Adopting microcomputer temperature controller with temperature protection and digital display, the temperature control is accurate and reliable;

3. The hot air circulation system consists of a fan that can continuously operate at high temperature and a suitable air duct, and the temperature in the working chamber is uniform;

4. Independent temperature limit alarm system, which automatically interrupts when the temperature exceeds the limit, ensuring safe operation of the equipment without accidents.