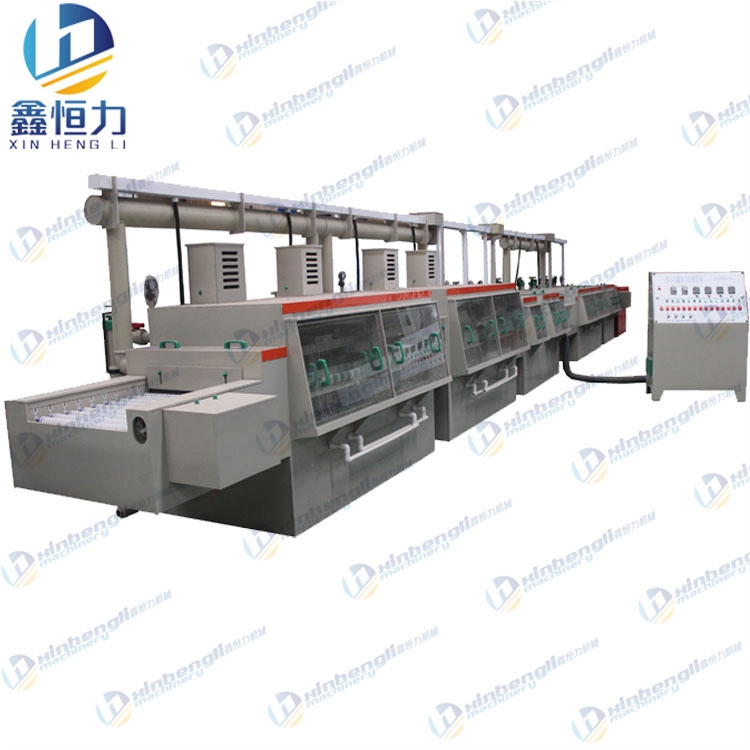

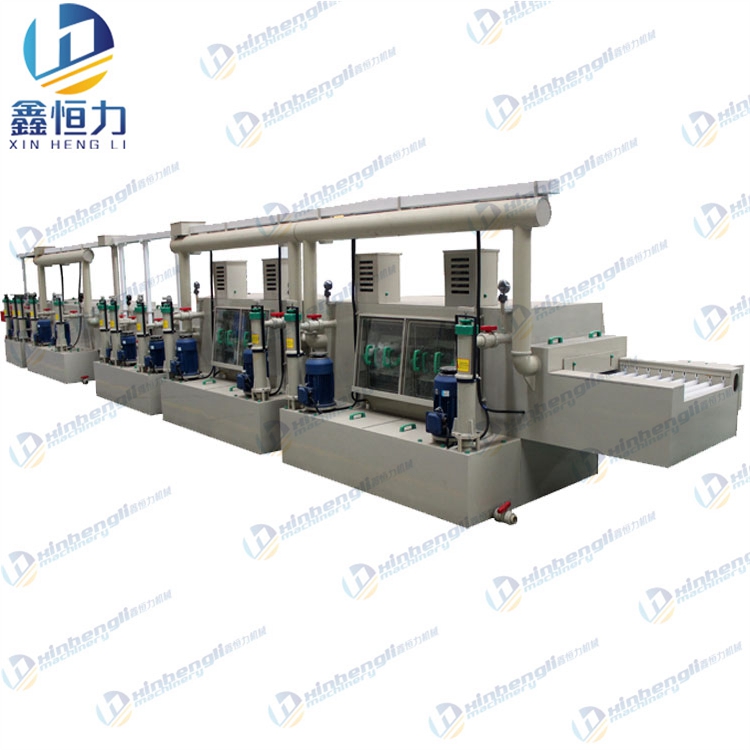

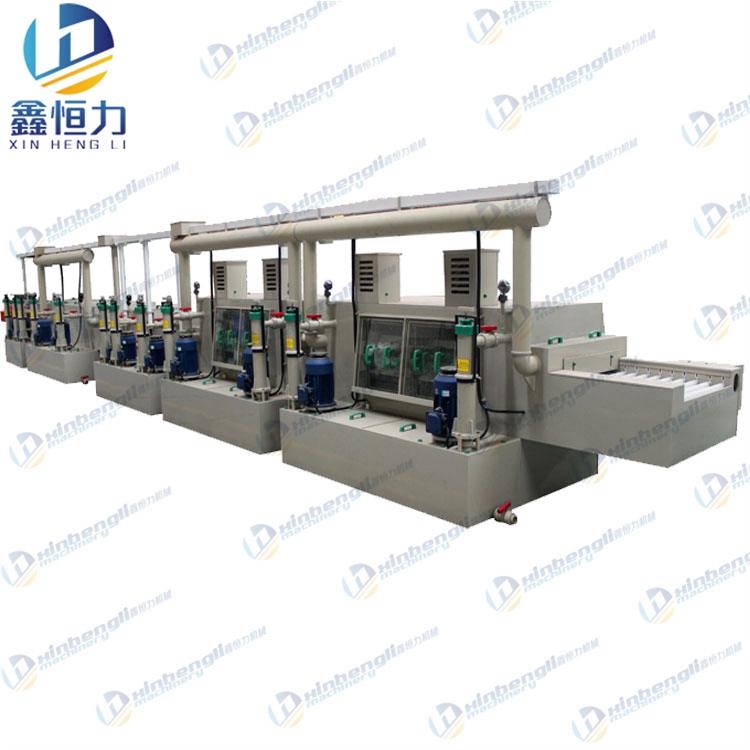

Equipment use:

The metal corrosion machine is mainly single/double-sided; the surface of the aluminum substrate is mainly etched, and is widely used in the PCB circuit board industry. The surface of the metal crafts is hollowed out, and the hardware accessories are single/double-sided etching. It is also the most advanced etching of metal corrosion. One of the machines is widely praised by customers for its stable quality and low price.

Process flow: feeding→4metre etching→3 grade water washing→checking→2metre film stripping→3 grade water washing→cold air drying→hot air drying→discharging

Machine parameters:

Machine model: XHL-DM74000TM;

Dimensions: 14980*1760*1600mm;

Etching area: 700*4000mm;

Stripping area: 700*2000mm;

Spray pressure: 3.5kg;

Etching pump: 4.0KW*4 units;

Cleaning pump: 2.2KW*6 units;

Stripping pump; 4.0KW*2 sets;

Heating pipe: 3KW titanium alloy heating pipe *3;

Water-cooled pipe: titanium alloy water-cooled pipe;

Spraying method: independent quick-release spray frame swinging spray;

Temperature control system: temperature display automatic heating system;

Filtration system: full pressure filter;

Power: 47KW;

Power supply: 380V/50HZ;