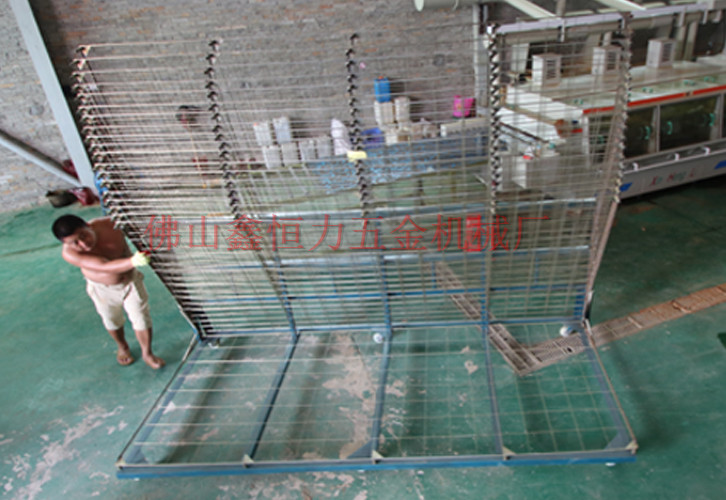

Hello, our factory specializes in producing a complete set of etching machine equipment to provide a full set of etching process technical support. This drying rack, lasagna rack and drying rack are a four-eight-foot ink drying rack specially designed by our factory for the etching process.

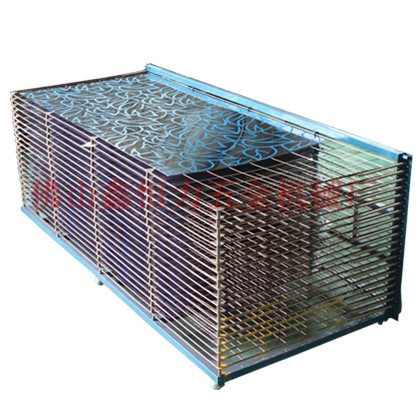

What kind of specifications can be produced in our factory? The surface of the mesh can be divided into galvanized, lacquered, dip-coated PE or PVC, and high temperature resistant hose. Acid and alkali resistant stainless steel drying rack and contracting dry refurbishment project, replacement parts and hardware processing business; mainly suitable for silk screen printing, computer version, glass technology, circuit board, ceramic, printing, wooden craft, PVC plastic Wait for storage, drying, baking and so on. The factory always adheres to the "quality assurance, service-oriented, reasonable price for business purposes, welcome new and old customers from all walks of life to send letters, calls, come to negotiate business": Your satisfaction is our pursuit.

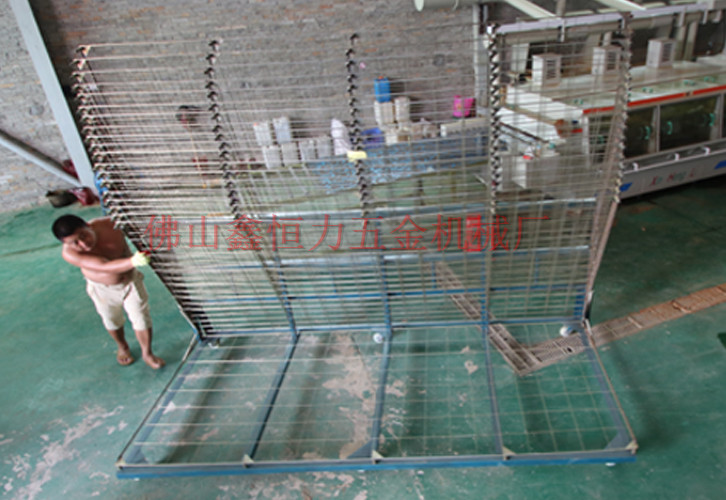

According to customer requirements, we can customize all kinds of specifications!

1. Design the applicable product according to your actual use;

2, according to the overall dimensions and specifications of the drying rack you provide, mesh size and application wire, grid size, mesh layer spacing, main frame casters, mesh technology, main frame technology, total mesh layer, number of fulcrums do. Casters: general wheel, white rubber wheel 120, temperature resistant wheel 180-360, iron wheel high temperature resistant mesh process: multicolored galvanized, white zinc, chrome plated, sprayed, powdered, stainless steel fulcrum type: iron triangle, square tube, According to your needs, the round tube can be customized according to the specifications of the various layers: conventional, non-standard

This drying rack is a drying rack that is not normally placed in the oven. If you need to enter the oven, you need to change the high temperature resistant casters. We accept the customization of drying racks with different specifications and different requirements:

1. Design the applicable product according to your actual use;

2, according to the overall dimensions and specifications of the drying rack you provide, mesh size and application wire, grid size, mesh layer spacing, main frame casters, mesh technology, main frame technology, total mesh layer, number of fulcrums do.

Casters: general wheel, white rubber wheel 120, temperature resistant wheel 180-360, pneumatic wheel, PVC wheel dust-free workshop, iron wheel high temperature resistance.

Mesh process: electroplating - plated multicolored - plated colorful, galvanized, chrome plated, sprayed, dusted, stainless steel

Pivot type: iron triangle, square tube, round tube.