Example; mainly introduces a Shandong customer to purchase a set of stainless steel sign corrosion machine in our factory. With the help of our whole process, we can stably produce in batches from the novice after 2 days of etching technology. Our factory provides a full set of stainless steel signs. Corrosion machine and supporting equipment, while providing free etching technology support, is an indispensable partner of the majority of sign corrosion processing plants. Let's take a look at the whole process from the novice to the independent mass production!

一. the customer asks for demand

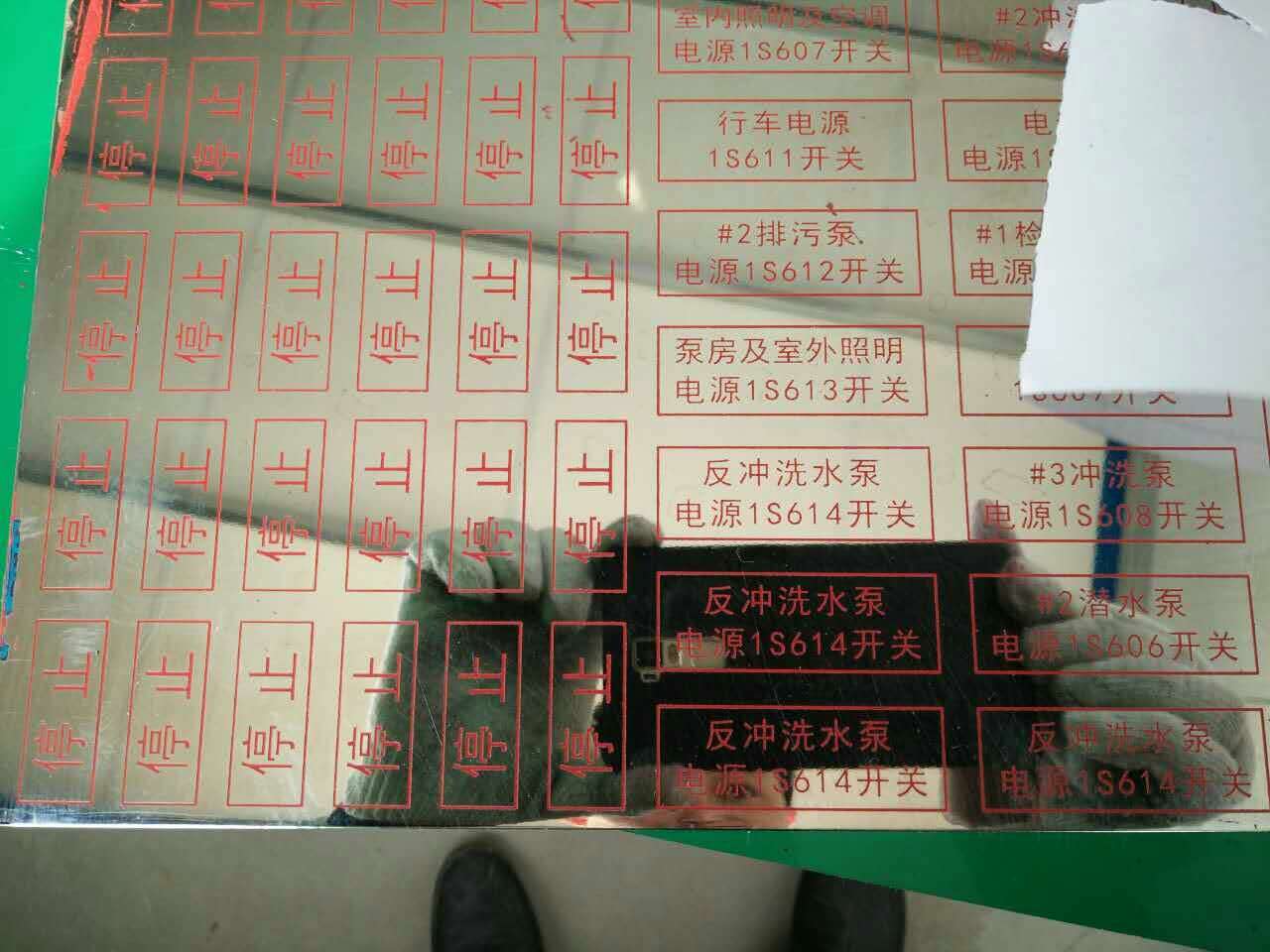

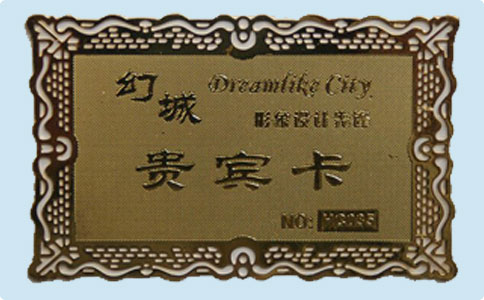

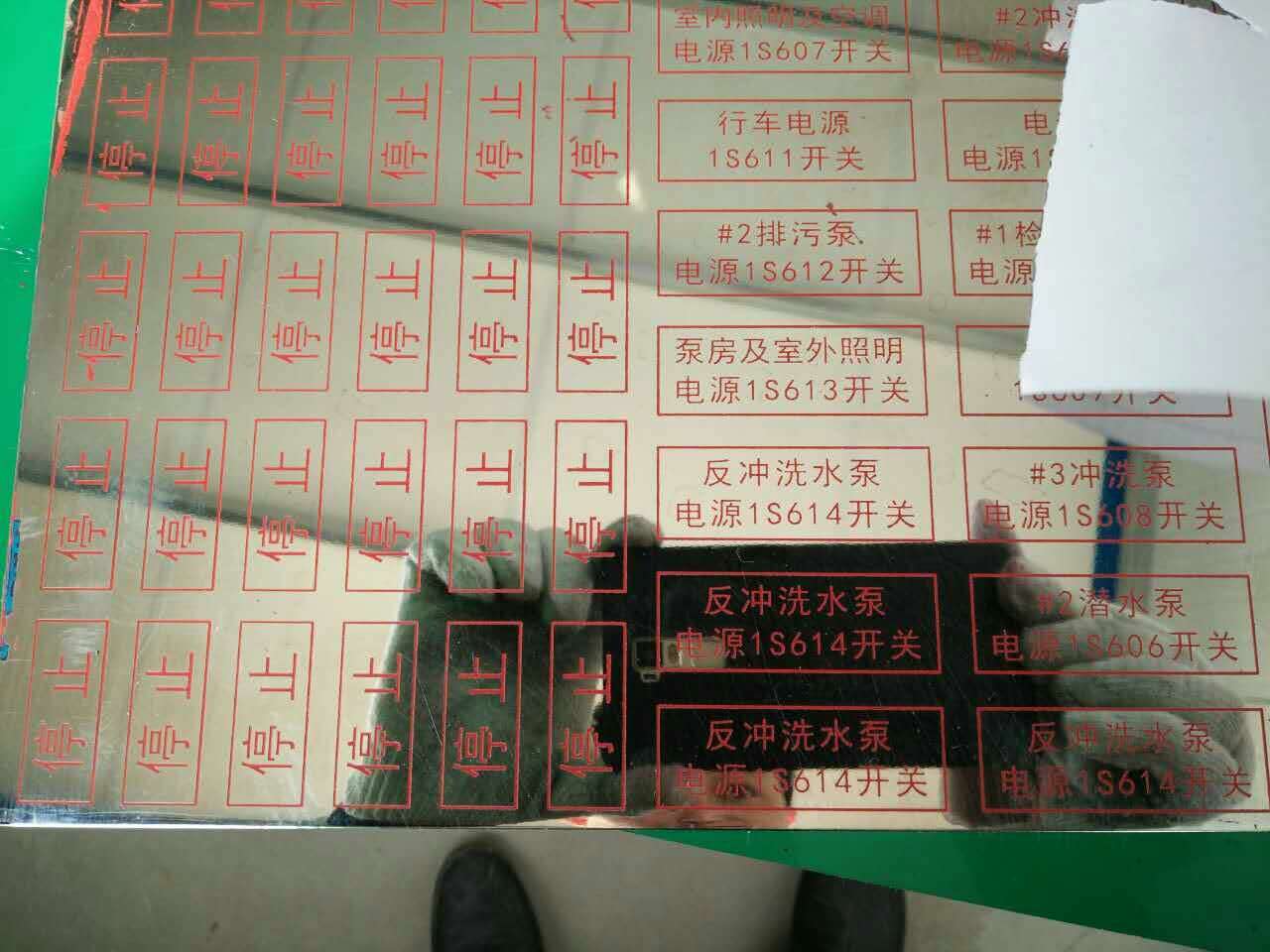

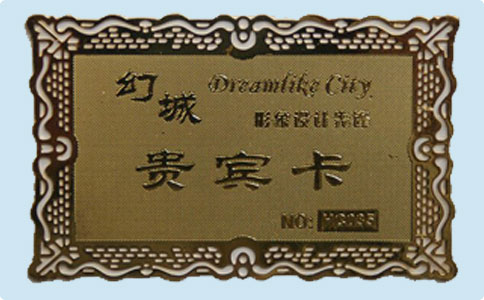

The Shandong customer learned through the network channel that our factory is a professional manufacturer of stainless steel sign corrosion machine. Through telephone communication, we know that the customer wants to produce and process stainless steel plate surface corrosion patterns, texts and logos, etc., collectively referred to as signage signs. Or billboards, the size is 200 * 400mm, the corrosion depth is between 0.2 ~ 0.3mm, the daily output is 150, and the image and text can be replaced. The product reference picture is as follows:

二. we give equipment plans and quotations

According to the above customer requirements, we will provide a device solution that meets the customer's requirements and has the lowest cost. Only three small devices can meet the needs of the customer. The three devices are:

Equipment 1: stainless steel sign corrosion machine, acting on deep corrosion

Equipment 2: blasted circulating oven, dry ink for image transfer

Equipment 3: exposure machine, curing protective layer ink

三. customer questions and answers

Question 1: What is the cost of a single sign corrosion product?

1. Cost accounting: 200 sets of equipment can be produced in 8 hours per day.

a. The labor cost is 2 people. Assuming an average daily wage of 250 yuan per day, the labor costs 500 yuan a day.

b. The cost of the syrup consumables is 120 yuan per day for 8 hours (no loss when the equipment stops production)

c. Hydropower cost, the total power of three sets of equipment is 9kw, the work of 8 small is 72 degrees, the electricity cost is about 72 yuan; the monthly displacement of this set of equipment is about 1 ton, the water fee is negligible

According to the above, the total cost is: 500+120+72=692 yuan. The number of workpieces that can be produced is 200 pieces. The cost of a single piece of 200*200mm size is: 692÷200≈3.5

Question 2: How is technology communicated?

Method 1: Edit the corresponding process steps and the ratio of the syrup formula to the customer by text mode

Method 2: Production video for the corresponding product

Method 3: Technicians verbally explain production points

Mode 4: The equipment is larger and sent to our technicians for on-site guidance.

四. reach a cooperation contract

Both parties confirmed that the above problems are correct. After the customer has confirmed the sales contract, the two parties faxed the agreement.

五. equipment custom shipment

The equipment required by this customer in Shandong is in stock, the customer informs us of the delivery, we arrange the delivery of the freight department.

六. the equipment arrived at the scene

After three working days, the equipment is safely delivered to the customer to make a position.

7. According to the plan given by our plan, the equipment placement position is energized.

After the equipment is delivered to the site, according to the sketch of the factory provided by the customer, we draw the accurate drawings of the factory, and the customer puts the equipment according to our drawings and then electrifies the equipment.

八. ready to start working

After the equipment is powered on in the customer's factory, the equipment is familiar with the process technology we have given before.

九. normal production

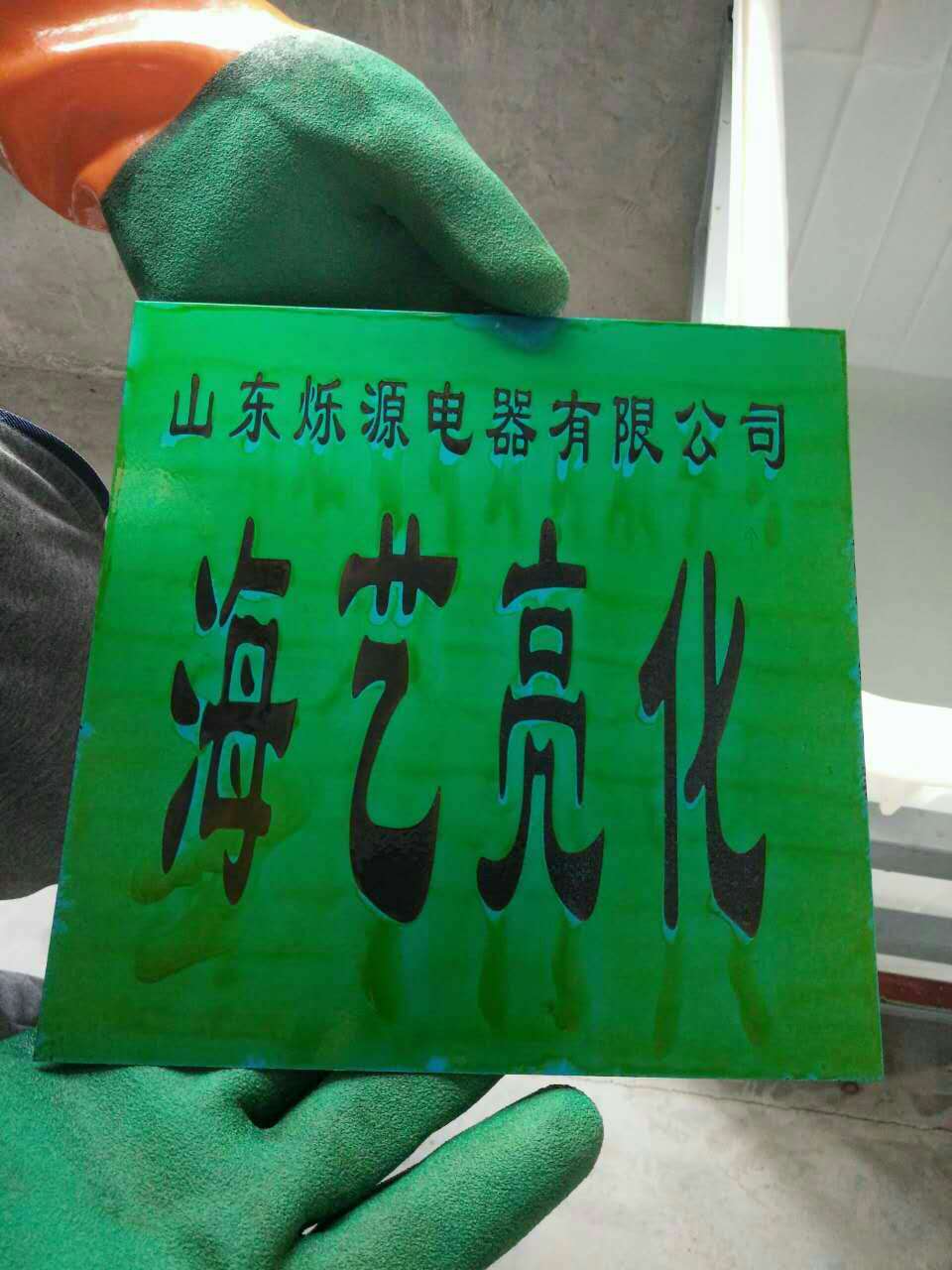

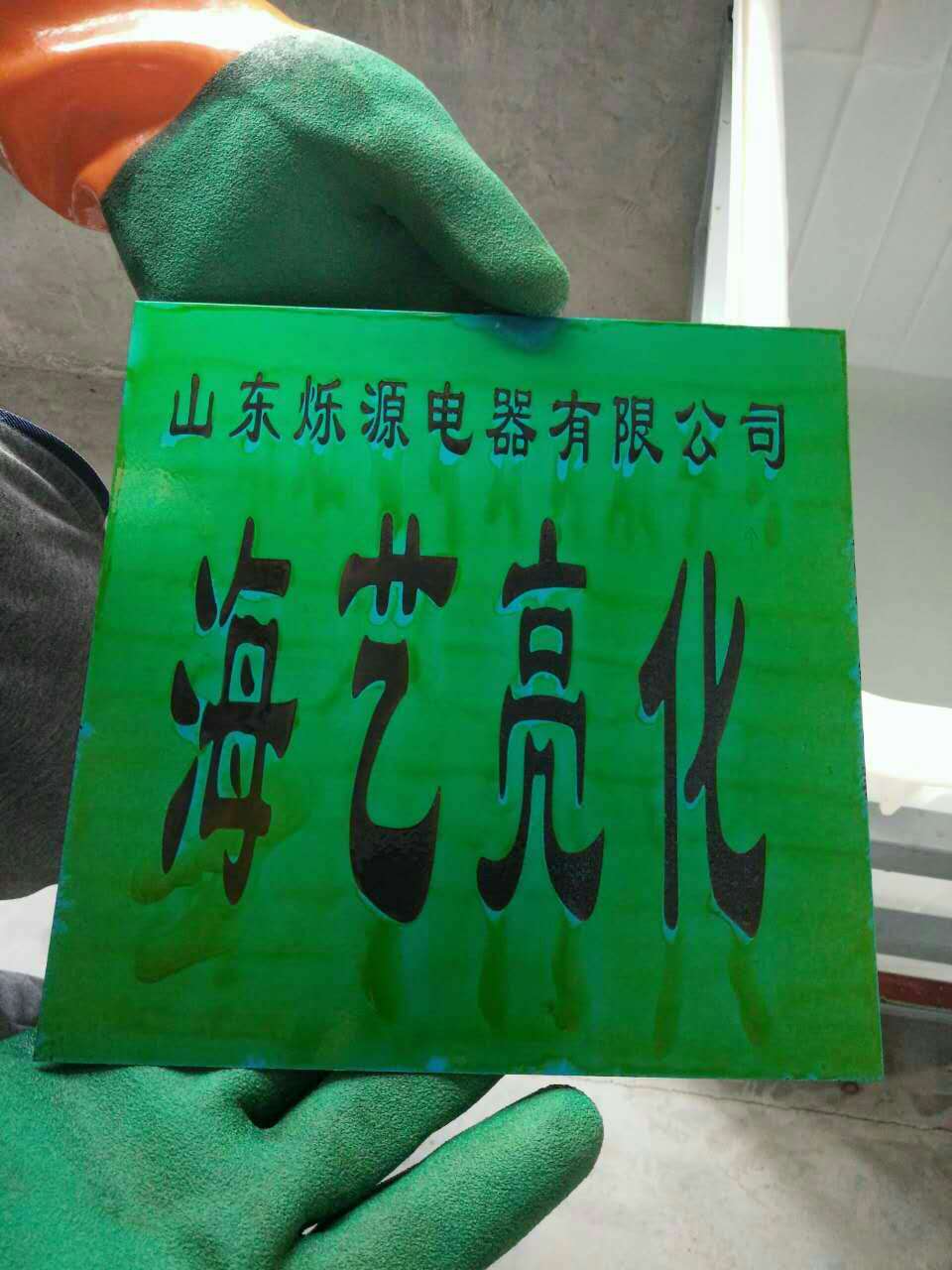

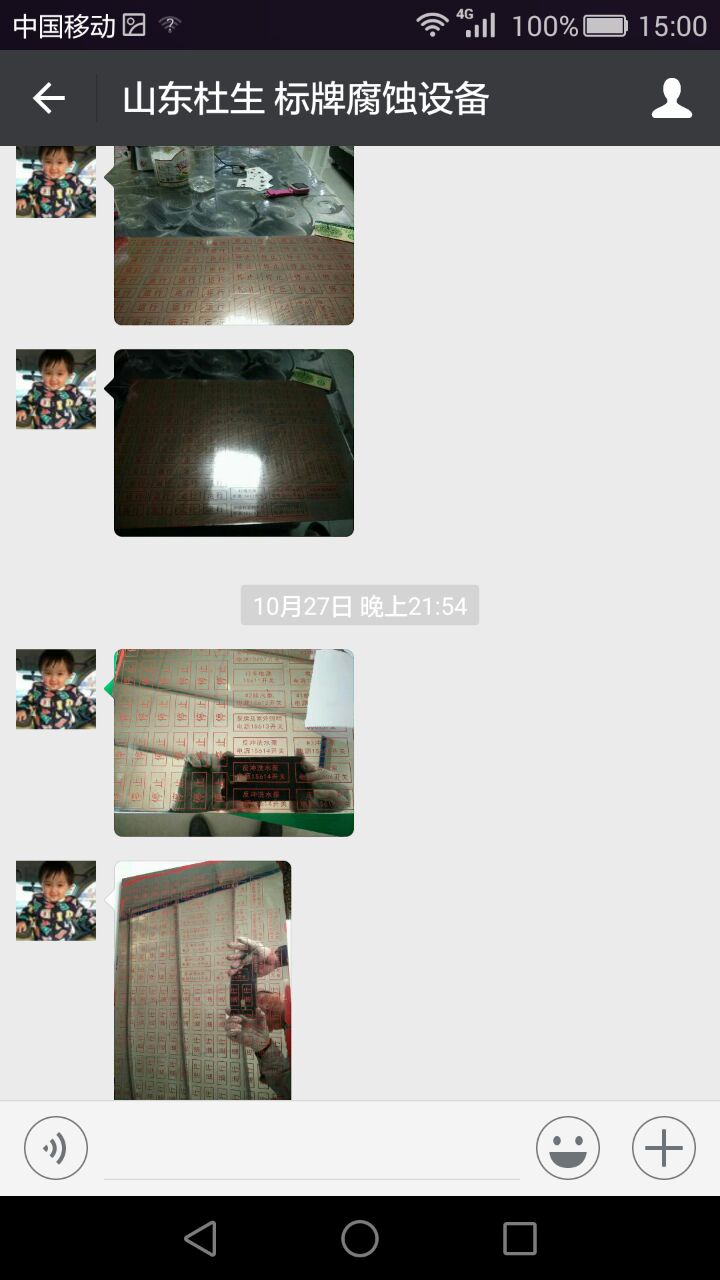

After our guidance and cooperation with the previous data, the first customer has the same batch production. The following is customer feedback details

Image transfer, etching, and coloring