The etching machine is mainly used for the corrosion processing of stainless steel decorative plates, also known as the flower board line. For the etching process, the plate of 1.22*2.44 meters can be produced and processed 250 pieces per day, and the daily production capacity is not less than 600 square meters, which is greatly improved compared with the previous production. The quality of the etching machine is also greatly improved. The whole machine is made of the most temperature-resistant engineering plastic PP. The PP for the hardware thick plate corrosion processing equipment is better than PVC. The reason is that the temperature resistance of PVC is not good. It is well known that the corrosion of the metal thick plate is quite high for the temperature of the syrup. Our whole machine uses PP plate and all of them are double-sided inside and outside welding to prevent deformation and water leakage. The bottom of the etching machine is fixed in multiple ways to avoid the big belly phenomenon. Friends of the corrosion machine should have experience. The most worrying thing is that the bottom of an etching machine can not withstand the temperature and gravity of the medicine, and the bottom will slowly deform and become a downwardly falling oval. After the opening, the whole machine can not be used, so in order to prevent aging, our factory resolutely resists the rough rotten, every etched factory All the machines must be inspected, and all the bad process parts are resisted. The accessories of our factory are also brand new. There is no second-hand refurbished. All the motors are imported source cards and then the pump heads are installed with anti-corrosion curing. The principle of multi-sale has won the trust of many customers at home and abroad, and this equipment has the largest share in the country.

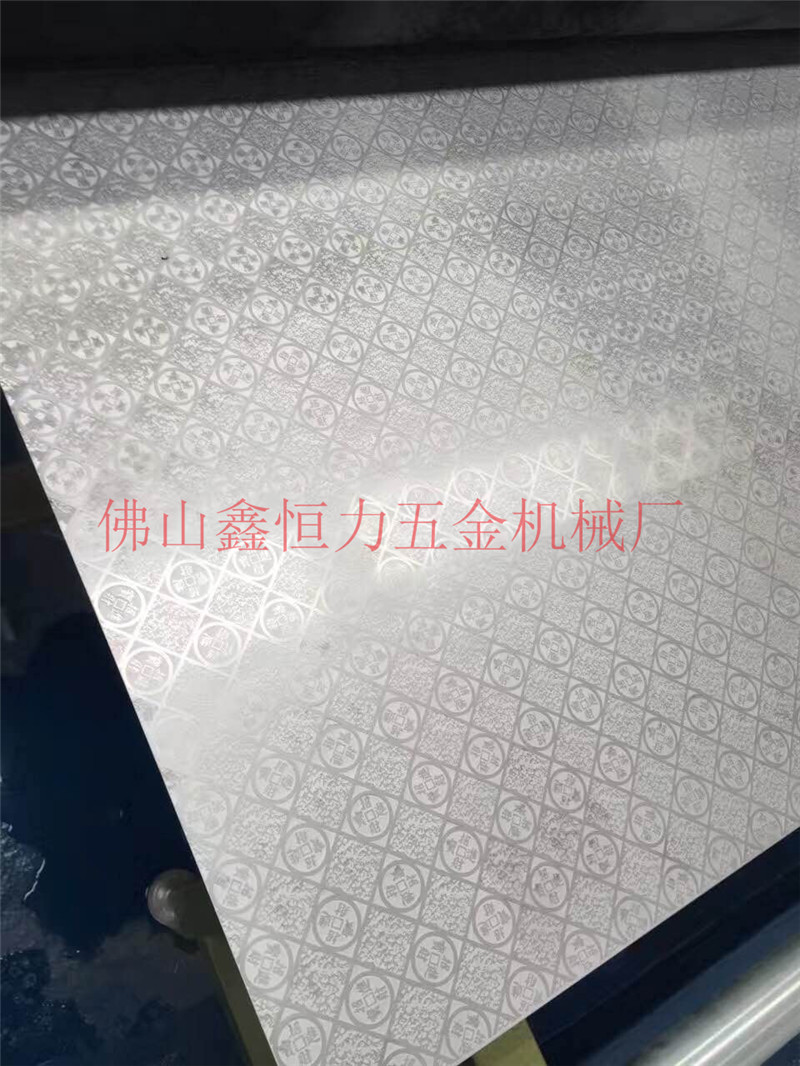

The effective etching zone of this etching machine provided by our factory is nine meters and the total length is 36 meters. It covers the entire etching process. After the transfer of the graphics, the machine feed inlet is finished. After the discharging, the finished product can be directly packaged. Let's take a look at the actual decorative trial production effect.

Etching machine parameters:

Power: 120KW;

Etching machine appearance

Elevator plate feeding

Inspection section

Discharge

Finished product

The factory was officially put into production and opened for celebration