Phone: +86 18927756652 (Wechat)

Etch machine_Etch machine Manufactor_Guangdong Xin Hengli equipment manufacturer

Landline: 0757-86677701

Web: www.fsxhljx.com

E-mail: 7587727@qq.com

Address: Guicheng, Nanhai District, Foshan, Guangdong Province, China

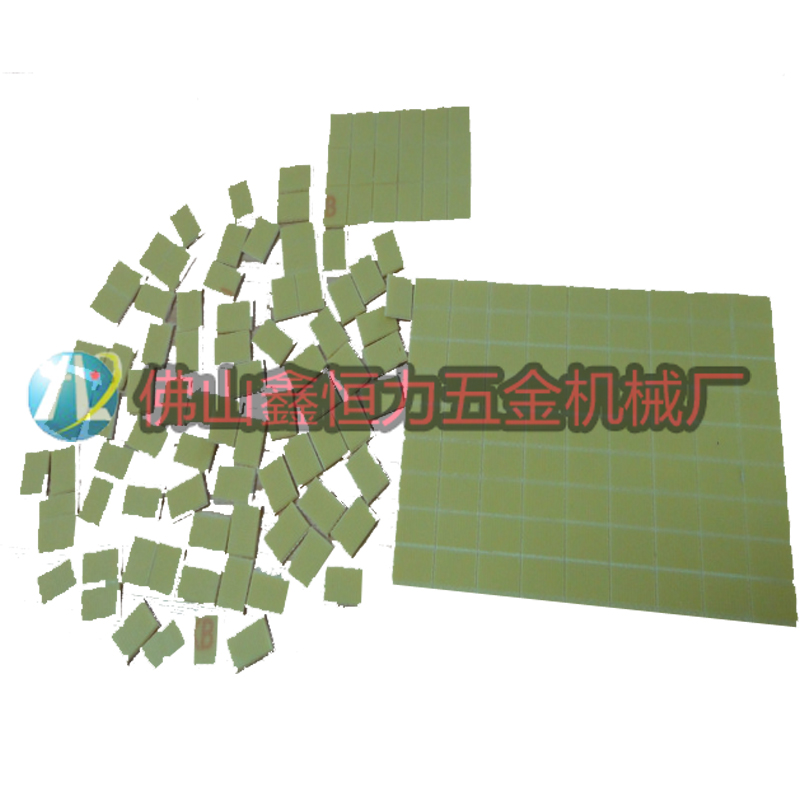

When V-cut is machined, it has automatic thickness control and residual thickness detection function, which can process all kinds of plates such as FR-4 and aluminum substrate.

| Product Name: PIN type V groove processing machine |

| Product number:VCM-660PN |

| product manual: |

|

Set of PIN type V groove processing machine VCM-660PN specification

< The design concept of the VCM-660 series meets the high precision and diversification requirements of the V-groove processing of the PCB, effectively reducing the processing into

this.

< Use computer Windows input and adjustment to reduce the possibility of personnel errors and improve yield.

< Production efficiency meets the production requirements of multi-blade circuit boards, and PIN alignment processing before molding is suitable for mass production.

< The thickness of the processing plate can be as thin as 0.3mm.

< Can process all kinds of plates such as FR-4, aluminum substrate, etc. in all directions.

< V-cut When machining, it has automatic thickness control and residual detection function.

< With the function of preventing collision and residual thickness, it can avoid the occurrence of artificial collision.

< High precision (+/-0.05mm) and high capacity (up to 40M/min).

< The tool motor uses a direct-coupled high-speed motor (15000r.p.m.) for good cutting quality.

< The base of the machine is integrally molded by casting, and the force is eliminated, the rigidity is strong, and the stability is good.

< Chinese interface circular operation, file management, simple operation, high stability, easy to learn, easy to understand.

< Automatic board width, board thickness, residual thickness and V-slot position setting (all controlled by servo motor and servo controller).

PIN type V groove processing machine VCM-660PN specifications

1, processing width, minimum 110mm ~ maximum 630mm

2, processing length, minimum 45mm ~ maximum 630mm

3, hole margin:

The distance between the center of the PIN hole and the nearest V groove is 8mm.

The leftmost PIN center is 8mm from the left side of the board, and each hole is 100mm apart.

The center of all PIN holes is 8 to 15 mm from the edge of the lower plate.

PIN hole diameter 3.175mm. (can be changed according to customer requirements)

4, processing plate thickness: 0.3 ~ 3.2mm

5, V-groove processing: up to 100 at a time (100 on the A side, 100 on the B side, a total of 200)

6, V-slot parallel accuracy &cjiamn; 0.05mm

7, V-groove spacing accuracy &cjiamn; 0.05mm

8, V groove residual thickness accuracy &cjiamn; 0.05mm

9, computer specifications: operating system WindowsXP Professional, screen: 17-inch LCD TFT

10, processing axis: Spindle: AC direct high speed motor 400W 2 sets, the number of revolutions 6000 ~ 15000RPM

11, tool specifications: φ120 * 2 * 25.4 * 20Z (30 degrees \ 45 degrees \ 60 degrees)

12, tool movement: 0.4Kw servo motor max. 60M/Min, can be set arbitrarily

13, processing speed: maximum 40M / Min (jumping knife 25M / Min), can be arbitrarily set

14. Jumping knife structure: The servo motor can be controlled by the servo motor, and the depth of the V groove is the center point of the upper and lower depth.

Small interval 15mm, processing data of skipping knife up to 20 pens

15. Processing clamp: move with 0.4Kw servo motor, moving speed up to 60M/Min

16, clamp: 6 use cylinder

17, Utility:

Electrical AC3φ 380V 2.5KW

AIR 0.5Mpa (5kg/cm2) 50NL/Min dry air

Dust collection connection surface φ100mm*1, minimum air volume: 15m3/min, minimum static pressure: 550m/mAQ

18, mechanical shape: (width) 2240mm, (deep) 1695mm, (high) 1326mm (including machine feet 100, without display

The height of the table is 920mm

19. Mechanical weight: about 1600kg

点击图标下载 App

|

|