Phone: +86 18927756652 (Wechat)

Etch machine_Etch machine Manufactor_Guangdong Xin Hengli equipment manufacturer

Landline: 0757-86677701

Web: www.fsxhljx.com

E-mail: 7587727@qq.com

Address: Guicheng, Nanhai District, Foshan, Guangdong Province, China

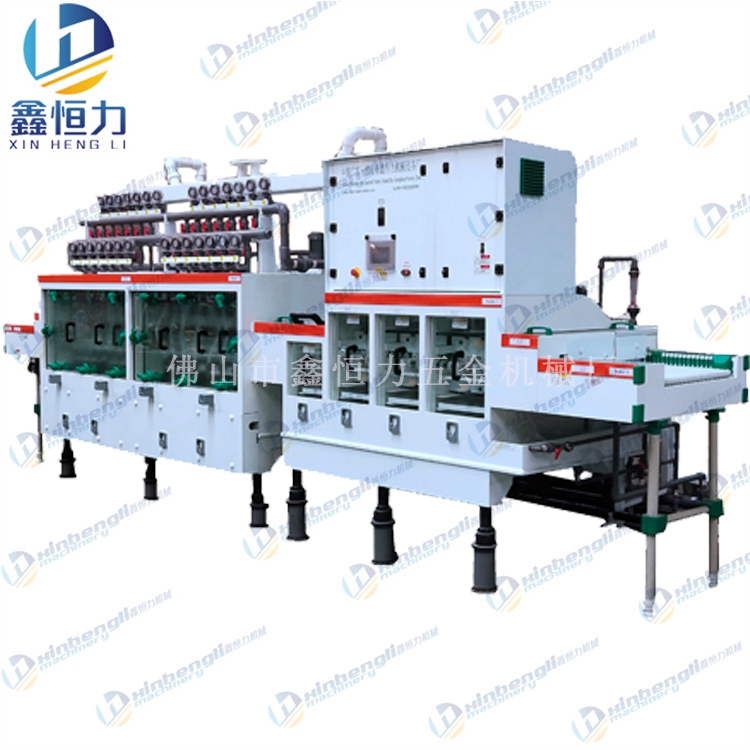

The surface of copper clad foil is chemically etched to remove unnecessary copper conductors to form circuit patterns. Technological process: into the board, etching, concentrated water washing, three-stage water washing, DI water washing, out of the board Machine description: Machine model: XHL-6M6024; Dimensions: 6024*2227*2700mm;

The surface of the copper clad laminate is chemically etched to remove unnecessary copper conductors to form a circuit pattern.

Process flow: input→ etching → centralized washing → cascade washing → DI washing → output

Machine description:

Machine model: XHL-6M6024;

Dimension: 6024*2227*2700mm;

Conveyor wheels: Φ32mm rubber coated wheels;

Wheelbase of row wheel: 25mm;

Width of conveying surface: 760mm;

Over board capacity: 0.05~2.8mm (board thickness);

Transmission speed: 0.5~5m/min (frequency adjustable);

Etching pump: 7.5HP*2 sets;

Vacuum pump: 7.5HP*2 sets;

Circulating pump: 3HP*1

Cleaning pump: 1HP*3 sets

Heating tube: 4KW titanium alloy heating tube*2;

Water cooling pipe: 25m titanium alloy water cooling pipe;

Filter system: full pressure filter;

Power: 36KW;

Power supply: 380V/50HZ;

Compared with the traditional PCB etching machine, the acid vacuum etching machine is suitable for fine line etching requirements. The use of a vacuum etching machine makes the line pattern with line width/line distance ≤30/30um easier to realize. Foshan Nanhai District Xinhengli Hardware Machinery Factory specializes in the production of etching equipment for more than 20 years and has rich experience. Welcome to visit our factory for business!